Molybdenum Disilicide Heating Elements

consisting of Molybdän-Disilizid (MoSi2) with ceramic additives.

consisting of Molybdän-Disilizid (MoSi2) with ceramic additives.

There are two qualities available:

MD 31: for max. element temperatur up to 1700 °C

MD 33: for max. element temperatur up to 1800 °C

Moly-D has the ability to withstand oxidation at high temperatures by forming a protective layer of quartz (SiO2) on its surface.

MOLY-D-Elements has a low specific electrical resistivity with a positive resistance-temperature characteristic. That means, if the temperature is increasing the resistance of Moly-D-Elements will increasing too. So, at a constantly voltage, Moly-D has a high element-power at a low temperatur which reduces the warm-up time of the furnace up to the operating-temperature and gives so an economical advantage

Because of its high temperature oxidation resistance, MOLY-D electrical resistance remains constant at constant temperature over its lifetime. This permits the use of old and new elements together in the same furnace, even if series-connected.

Typical application range for MOLY-D-Elements are:

- steel industry

- metal working industry

- glass industry

- ceramic industry, as well as laboratory furnaces

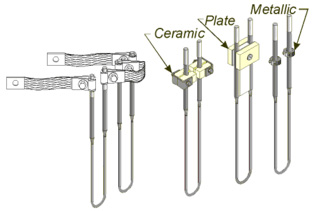

delivery forms:

2-shank bent elements are available in the following standard sizes:

| typ | terminal-diameter Lu | heating-zone-diameter Le |

| 3/6 | 6 mm | 3 mm |

| 4/9 | 9 mm | 4 mm |

| 6/12 | 12 mm | 6 mm |

| 9/18 | 18 mm | 9 mm |

| 12/24 | 24 mm | 12 mm |

Elements with cranked heating-zone or terminals are also available.

Spacing between shanks:

| typ 3/6: | a = 20 / 25 / 40 mm |

| typ 4/9: | a = 20 / 25 / 40 mm |

| typ 6/12: | a = 40 / 45 /50 / 60 mm |

| typ 9/18: | a = 50 / 60 mm |

| typ 12/24: | a = 60 / 80 mm |

(other sizes and 4-shank elements available on request)

Max. length of heating-zone depends on element temperature

which is for

| 3/6 elements: | 610 mm |

| 6/12 elements: | 1250 mm |

MOLY-D-Elements are defined by:

- Material quality

- Diameter heating-zone in mm

- Diameter terminal in mm

- Terminal-length in mm (Lu)

- Heating-zone length in mm (Le)

- Spacing between shanks in mm (a)

example: MD-31, 6/12 mm, Lu = 400 mm, Le = 500 mm, a = 50 mm

Our Delivery programme also includes compatible metallic and ceramic brackets, connecting bands and furnace ducts.