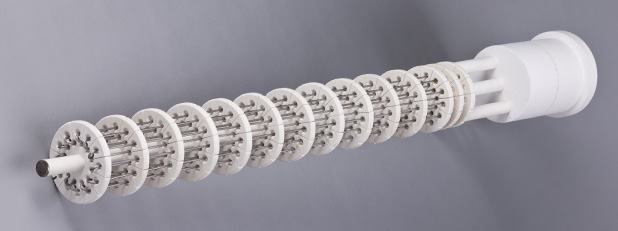

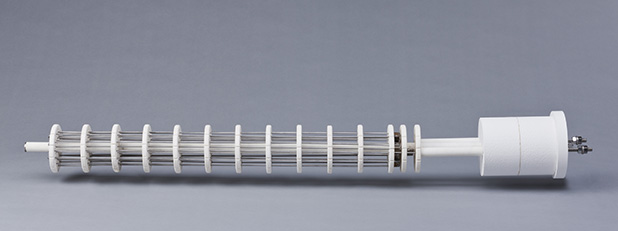

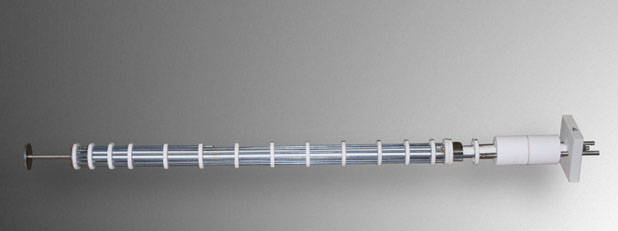

Cage elements

Cage elements consist of metallic parts and ceramic, electrically non-conductive parts such as ceramic plates or spacers. The metal centre rod is necessary to bind the ceramic parts together.

CONSTRUCTION:

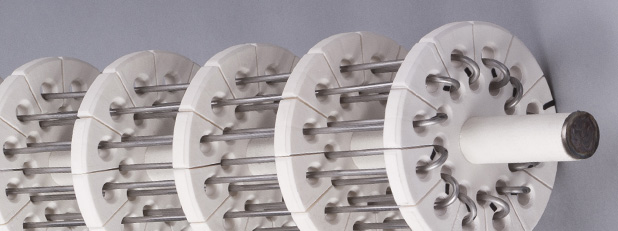

Holes in the ceramic plates receive the heaters, which in this way are kept electrically insulated from each other. The insulating gap is situated at one end and it is important that is goes from the hot side to the cold area in order to allow the cable to connect to the power supply. The insulation distance can optionally be created by ceramic vacuum formed parts or conventional refractory bricks (further construction requirements can be fulfilled according to customer specifications).

Heaters can be made from approved CrFeAl alloys or from NiCr alloys from our product range. Depending on temperature or atmosphere, a choice must be made as to which of the two classes above will lead to a longer product life for individual use (we can provide you with technical support for this).

Cage elements from Berghütten, in contrast to conventional cage elements, offer features, such as floating ceramic subfloor heating, which ensure that the full temperature range is used and that no unwanted interaction between the ceramic parts, which have different rates of expansion, takes place.

Application fields:

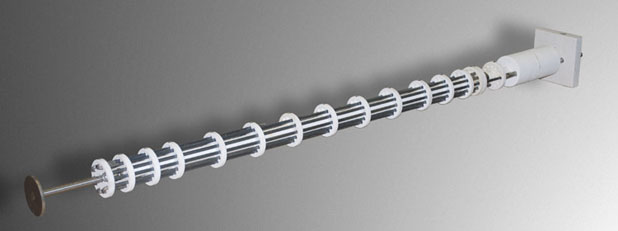

Cage elements may be operated in a horizontal position with a branch pipe or in a vertical position with or without a branch pipe. This setup must be decided individually based on the application. Cage elements are mainly employed in continuous furnaces, multi-purpose chamber furnaces or furnace applications where there is a corrosive atmosphere.

Application areas:

The maximum of the heating element temperature range is 1250°C for CrFeAl alloy and around 1150°C for CrNi alloys. The standard lengths vary from 400 mm to 2000 mm, which is empirically speaking a very good range for practical use. Other lengths can be produced according to customer requirements and taking into account construction conditions. The installable output is dependent on cage element diameter, length, heating element material and furnace temperature.

Safety equipment:

To prevent the heater from overheating, it is recommended to use one safety thermocouple per element or at least one per heating zone.

Accessories:

We can supply you with branch pipes and heating conductors of various grades for horizontal mounting of cage elements. In addition, we can include other components, such as connecting bands for high temperatures and trestles, with the delivery, in order to ensure optimal use of the cage element.

In this way, we ensure that every application need is met with a comprehensive solution which results in fast and reliable operation for the customer.

The diagram shows the maximum possible installable output for a cage element per metre, as a function of furnace temperature and diameter of the cage element plate.