Heating registers for forced-air ovens

Heating registers are a collective term with Berghütten for concentrating several heating elements to produce a larger self-contained unit. Generally, heating registers are used for generating warm or hot gases used for a wide variety of processes or applications in the area of electric heat. That ranges from laboratory furnaces all the way to combustion chambers where heating register heat gases to as much as 1,200 C°. These furnaces are also used to give materials such as steel or glass new and streamlined properties with thermal processes.

Heating registers are a collective term with Berghütten for concentrating several heating elements to produce a larger self-contained unit. Generally, heating registers are used for generating warm or hot gases used for a wide variety of processes or applications in the area of electric heat. That ranges from laboratory furnaces all the way to combustion chambers where heating register heat gases to as much as 1,200 C°. These furnaces are also used to give materials such as steel or glass new and streamlined properties with thermal processes.

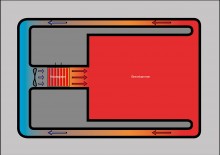

Generally, the gas flowing through the heating register in a channel (convection heat) is heated up before it comes into the combustion chamber to generate a homogenous temperature in it. Here, the size, number and arrangement of the heating elements are designed within the installed heating registers in accordance with the temperature required in the furnace which means that one or several heating registers are used depending upon the size and temperature demanded in the combustion chamber.

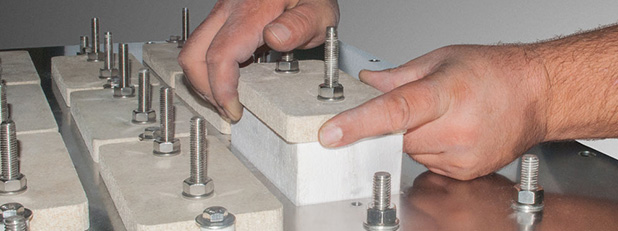

Custom-made heating registers

Berghütten has been coming up with, planning and building heating registers for decades in a wide range of designs and performance classes ranging between 600 and 1,200 C°, although even higher temperatures can be achieved depending upon the design of the heating register or furnace. For instance, they are used for stress-free annealing of steel and glass as well as a many other applications. We engineer heating registers for the materials to be treated as per the thermal processes needed while providing the furnace builder our expertise in all issues concerning our heating registers.

Berghütten has been coming up with, planning and building heating registers for decades in a wide range of designs and performance classes ranging between 600 and 1,200 C°, although even higher temperatures can be achieved depending upon the design of the heating register or furnace. For instance, they are used for stress-free annealing of steel and glass as well as a many other applications. We engineer heating registers for the materials to be treated as per the thermal processes needed while providing the furnace builder our expertise in all issues concerning our heating registers.

The heating registers shown on these and the following pages are iconic for a wide variety of heating registers produced by Berghütten that we develop and produce in accordance with the specific needs of our customers.